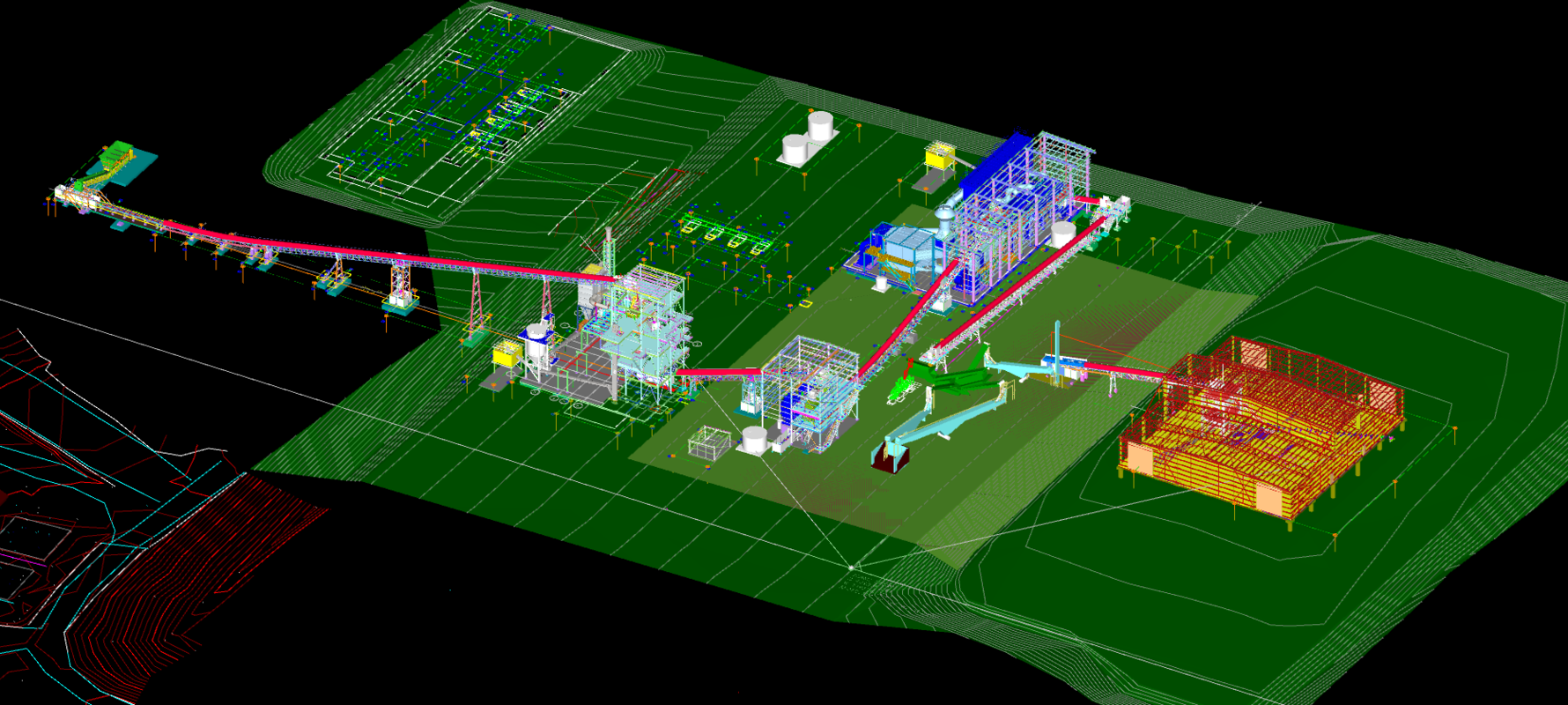

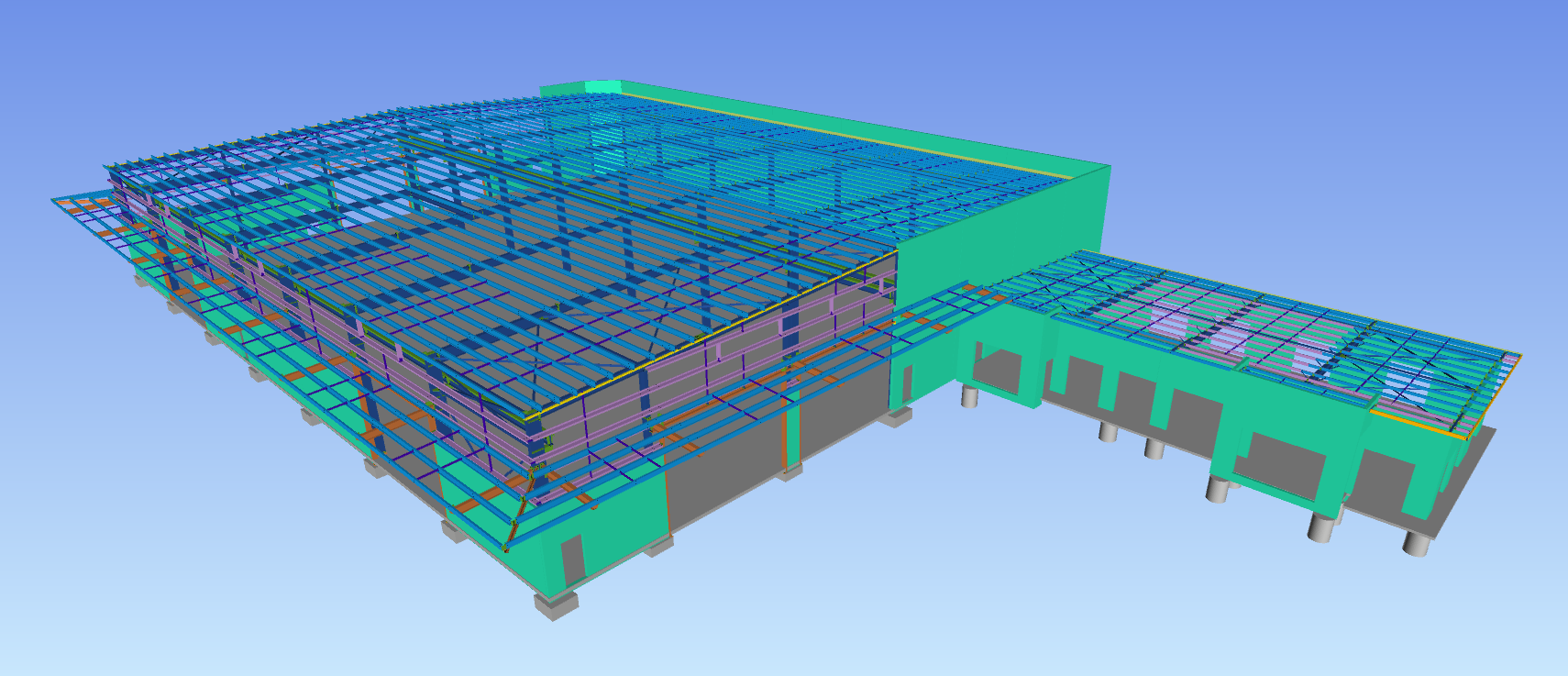

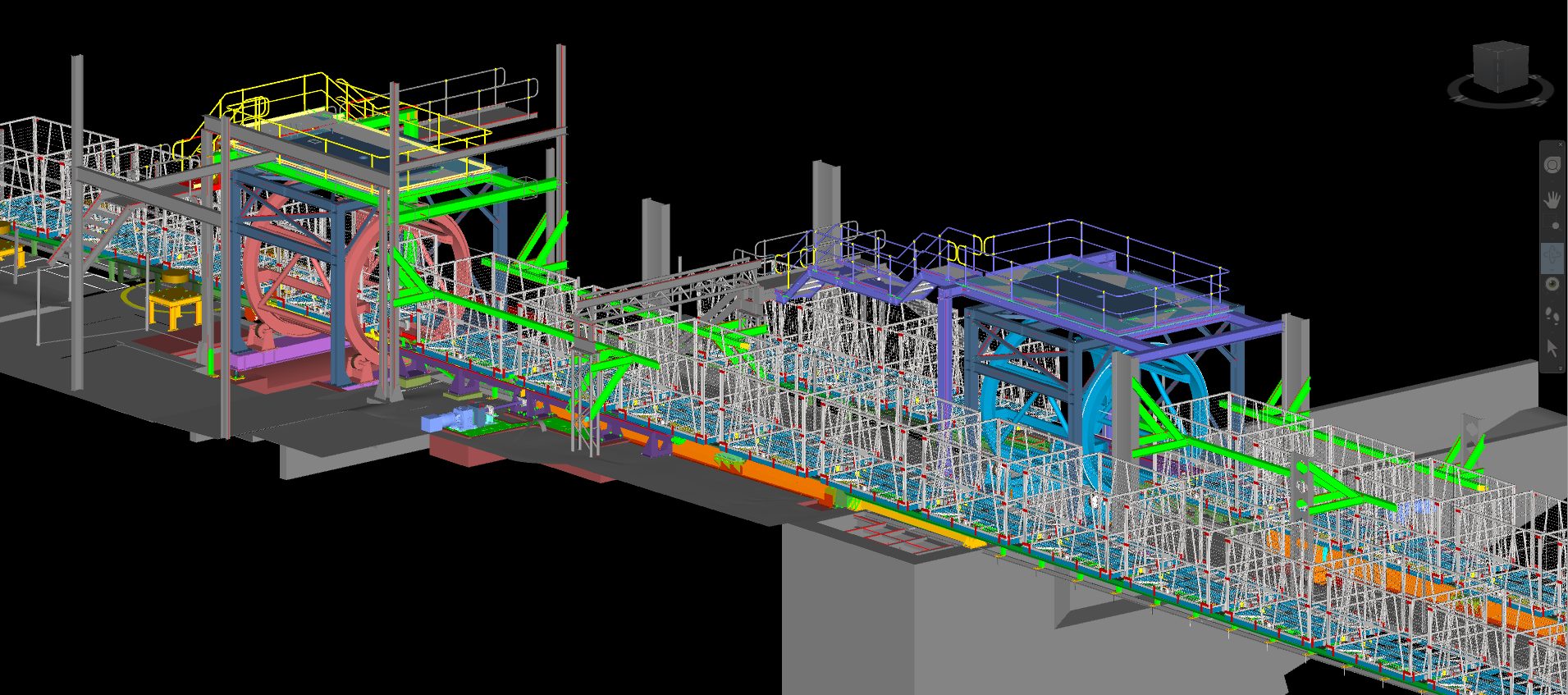

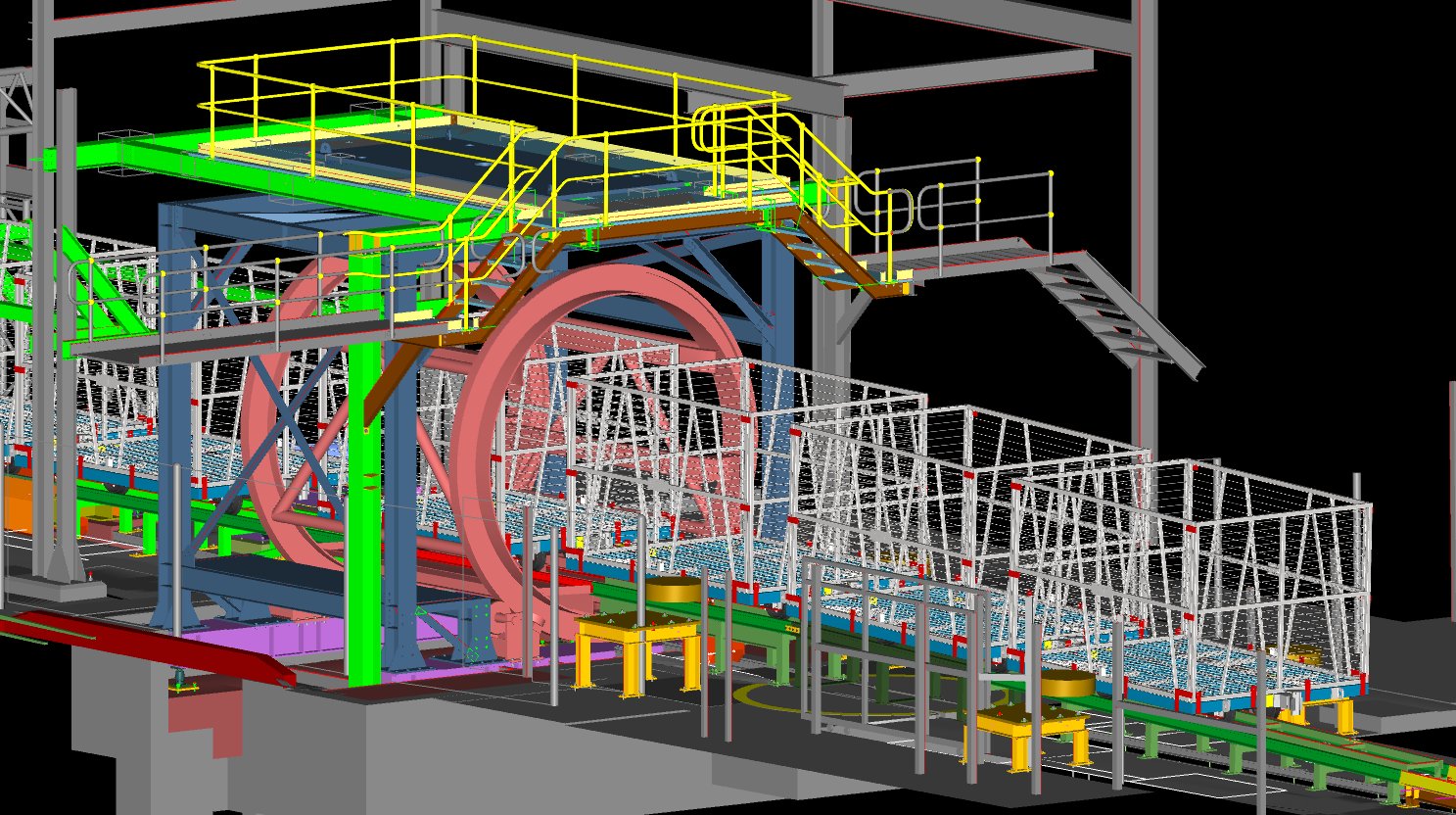

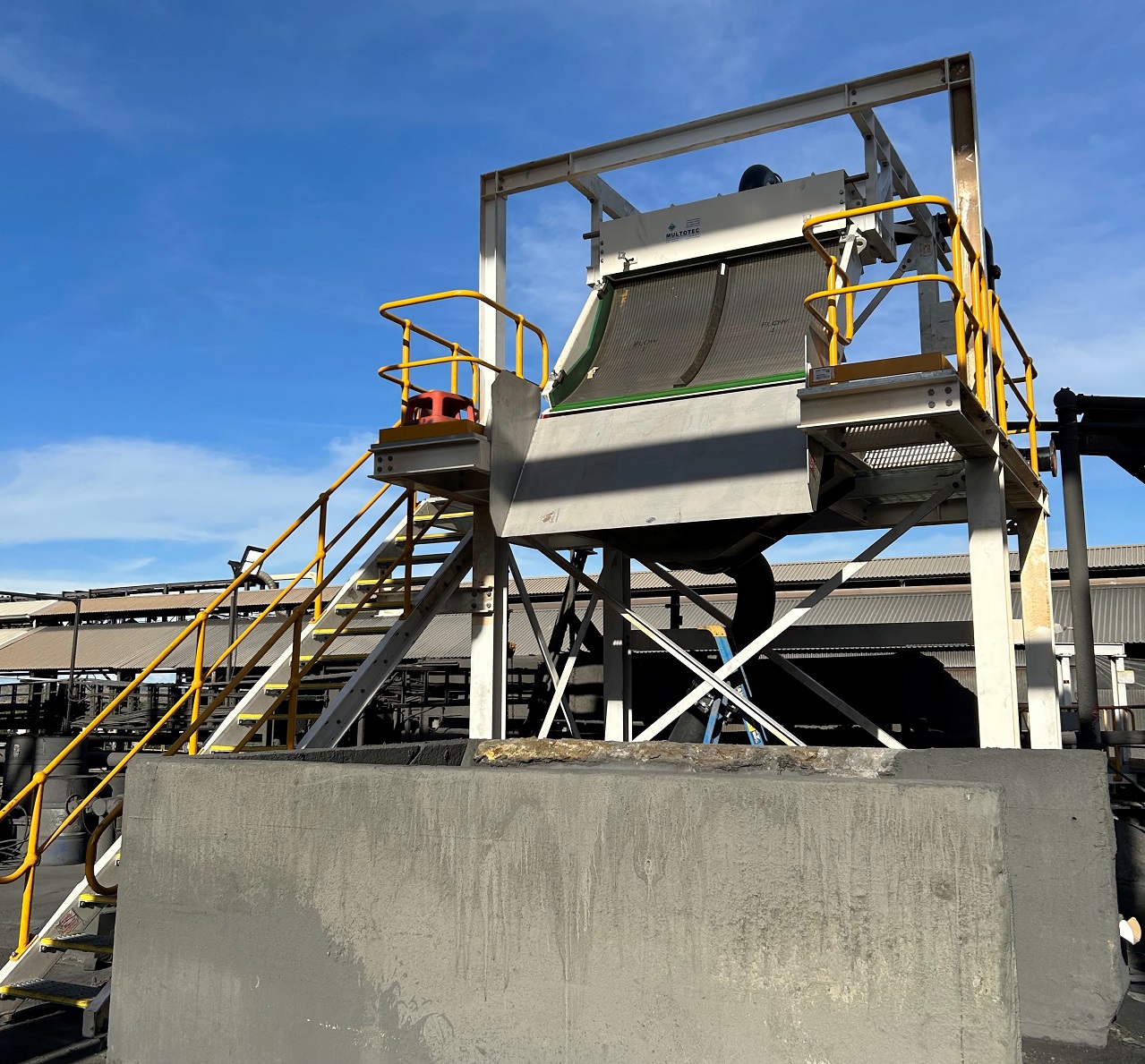

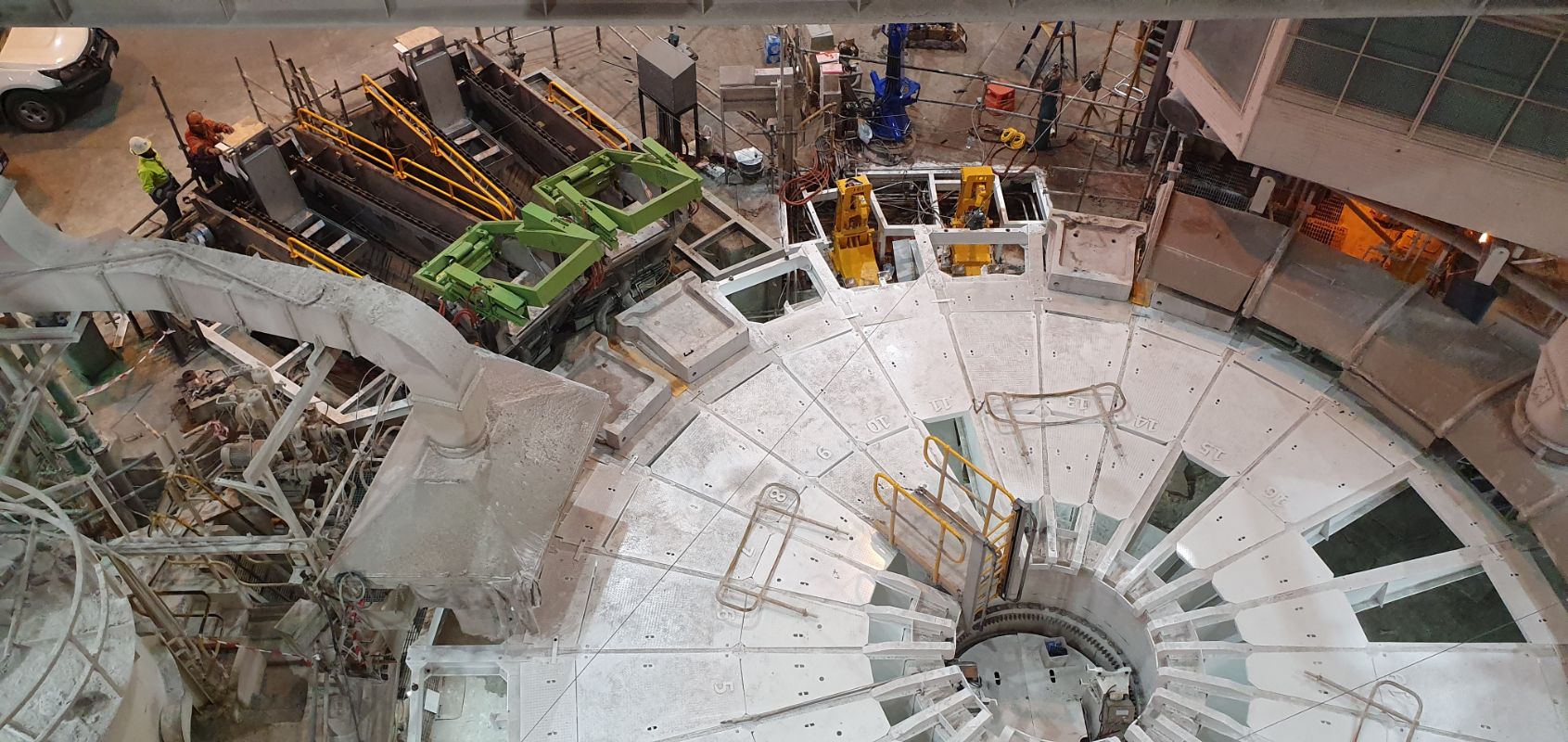

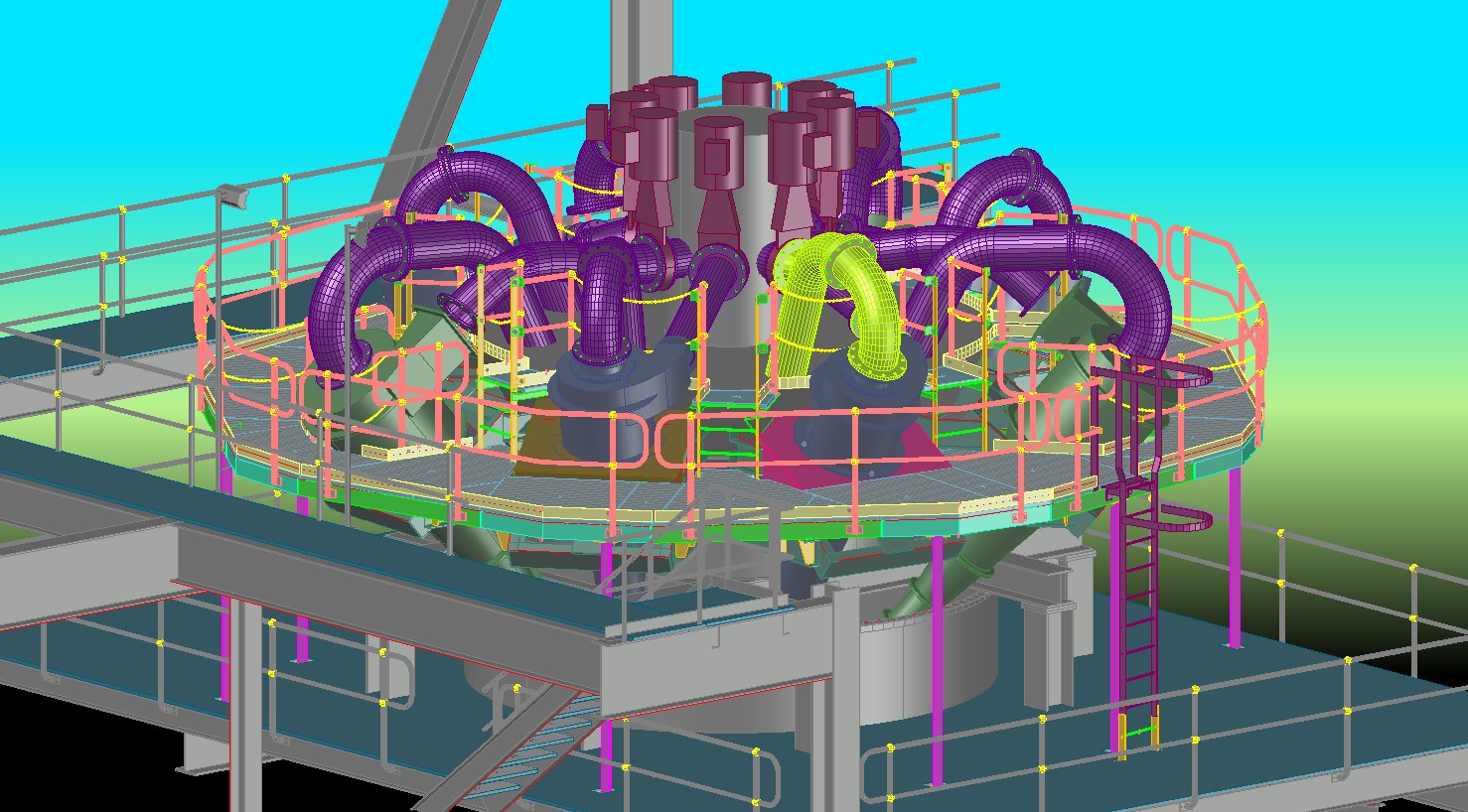

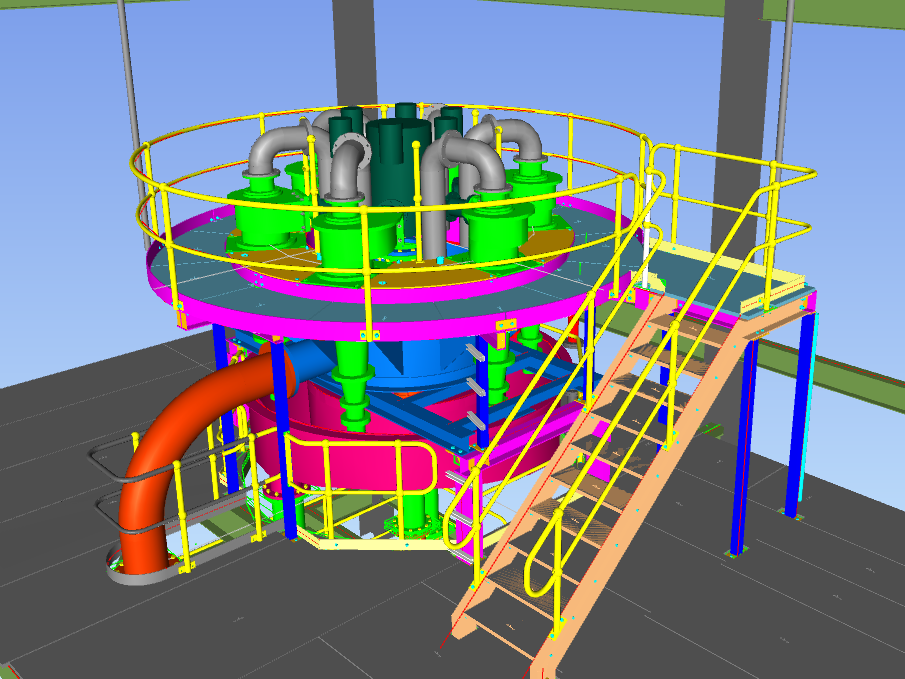

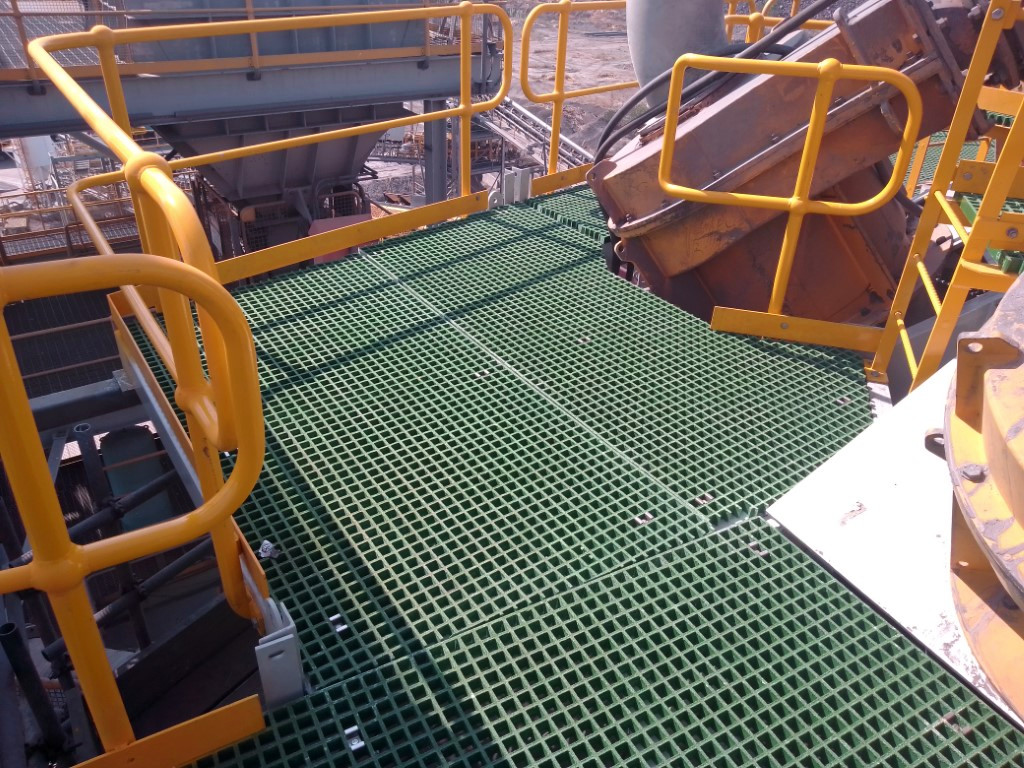

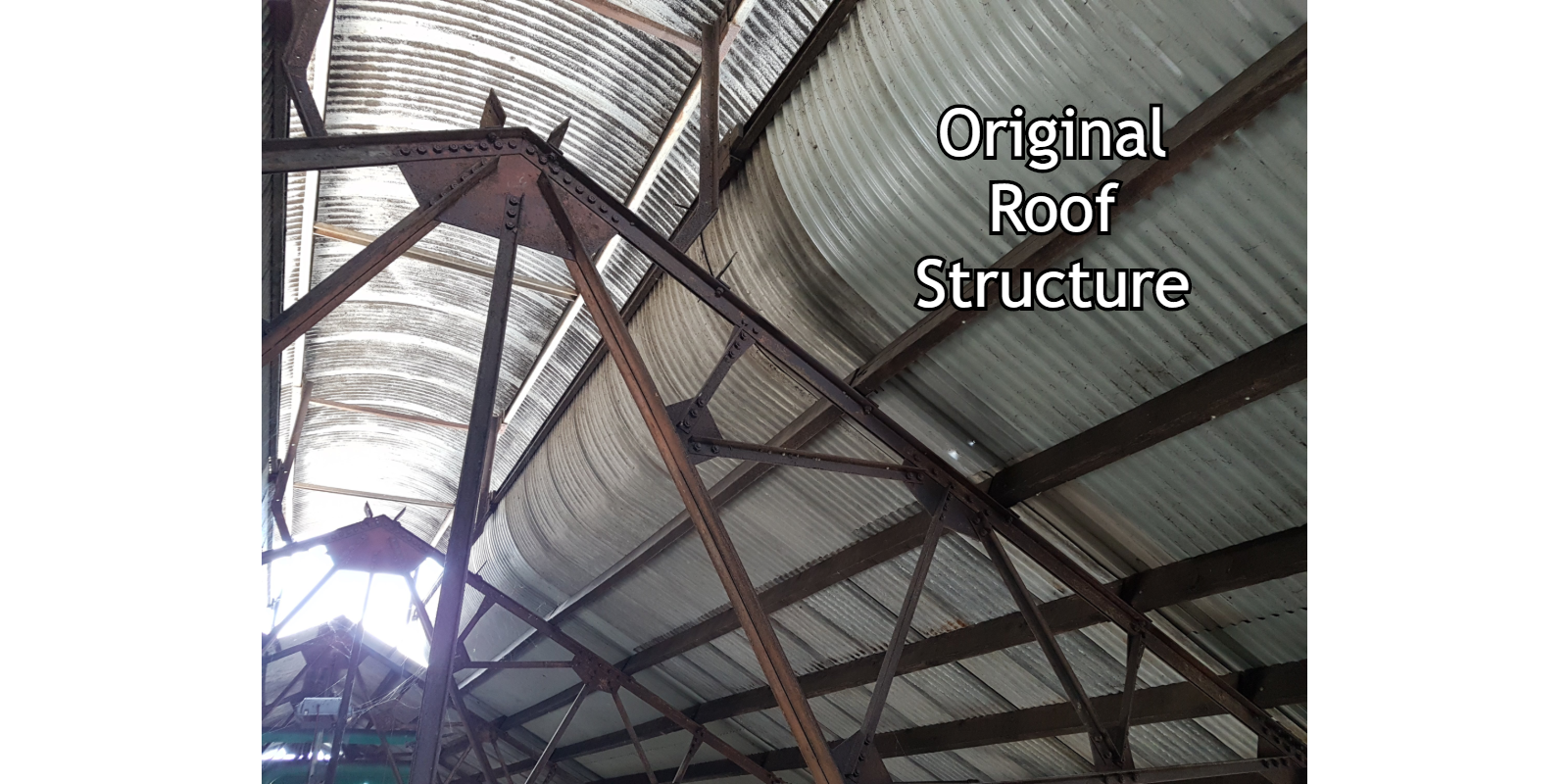

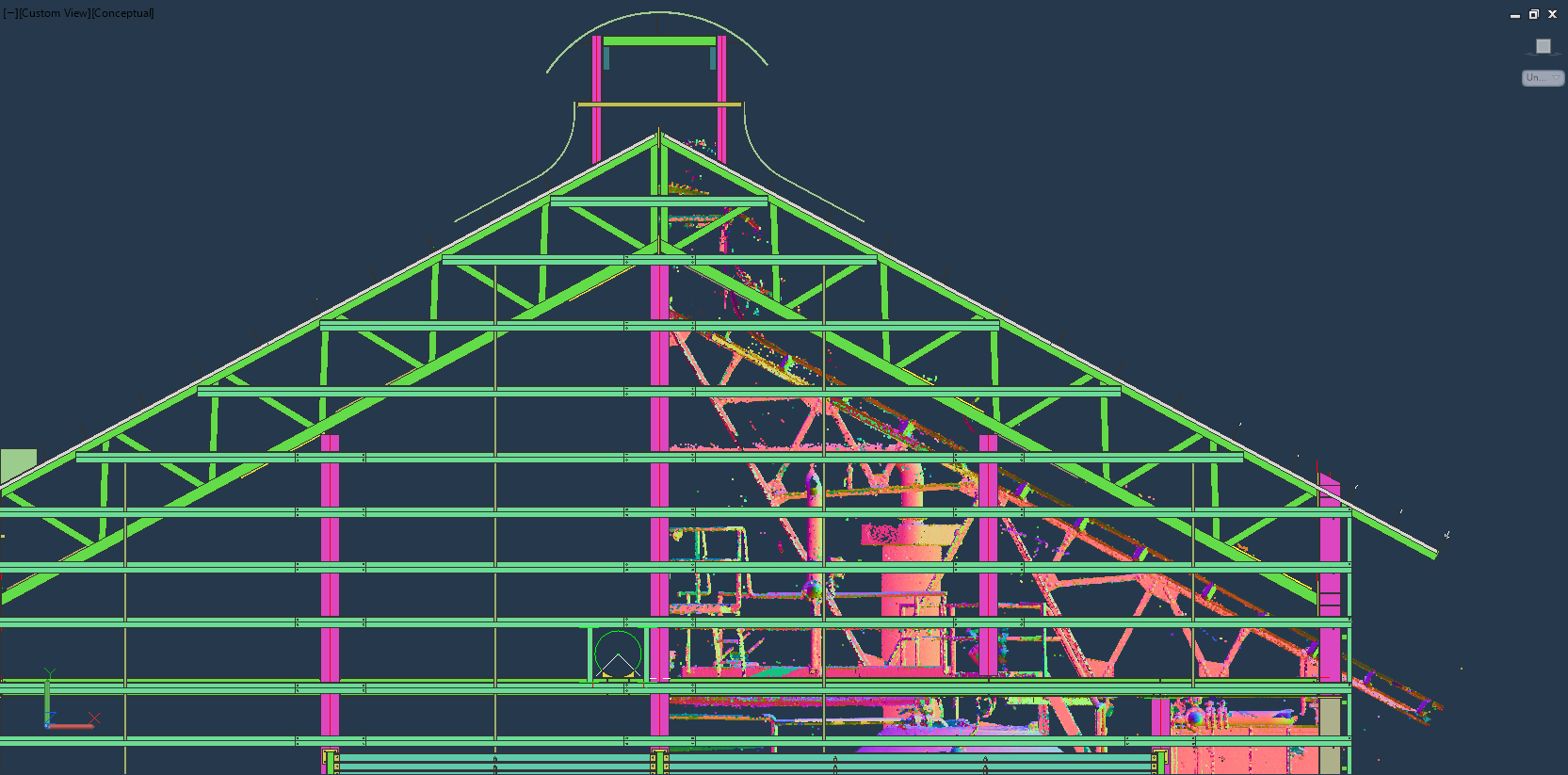

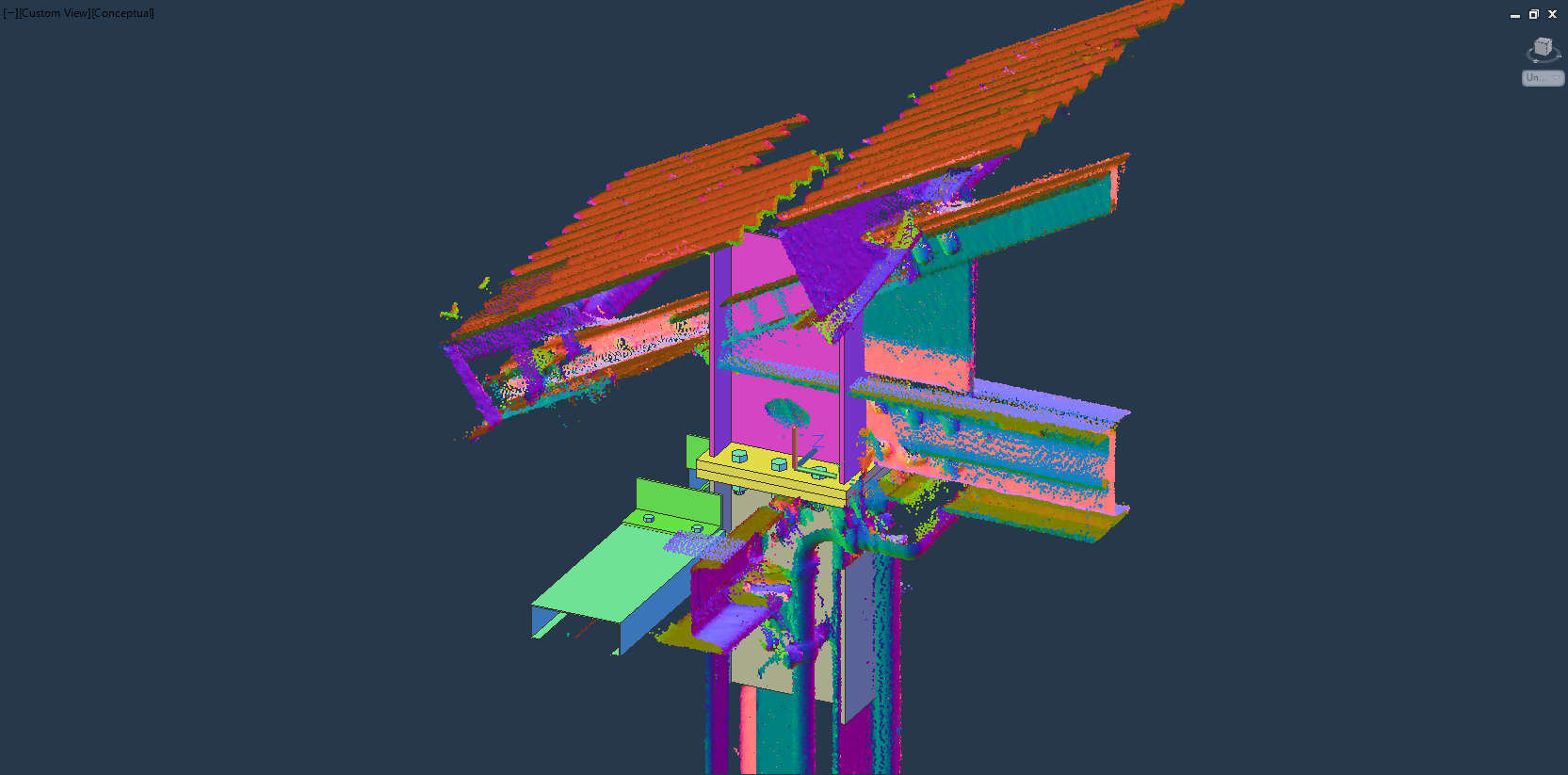

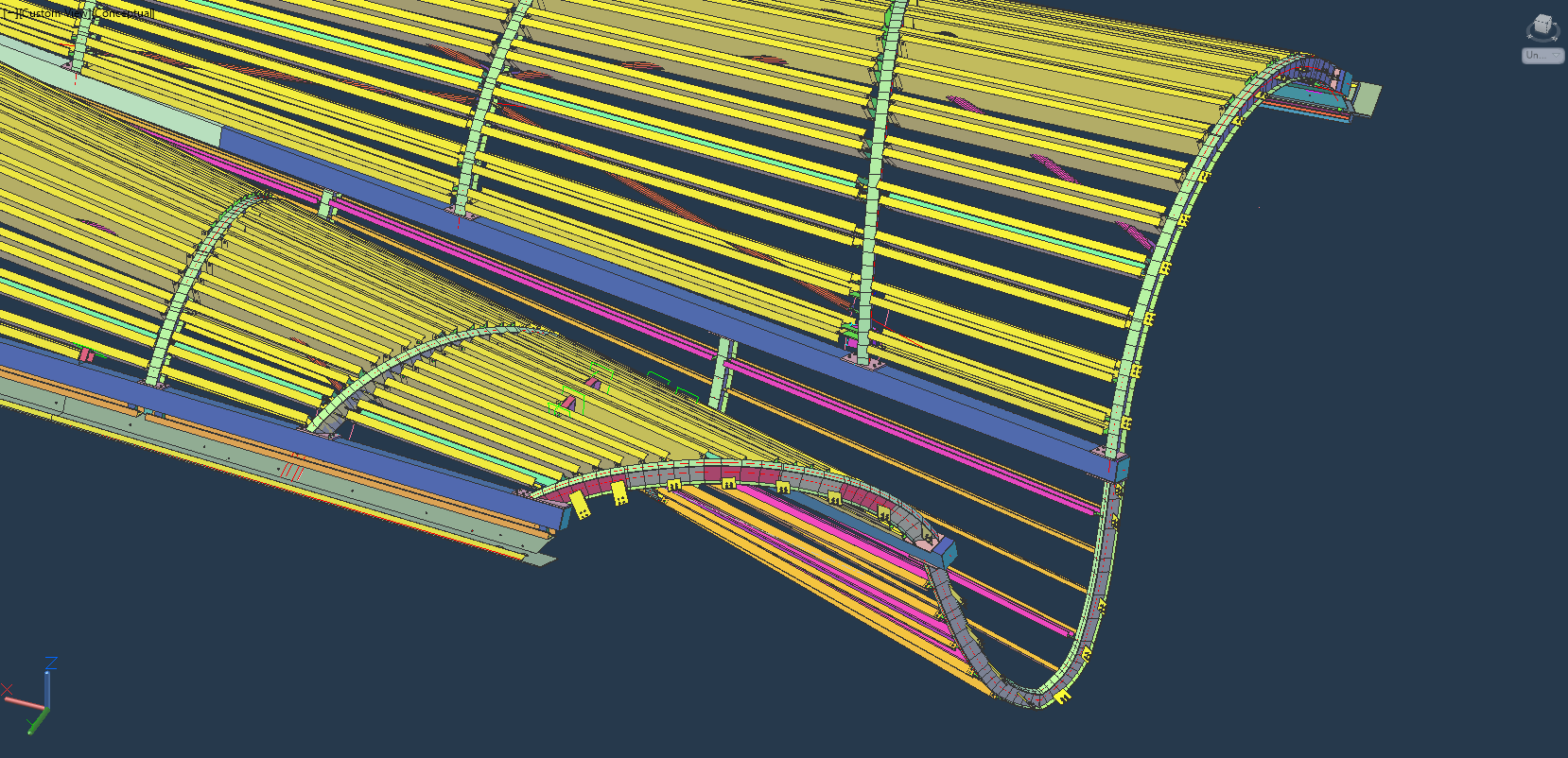

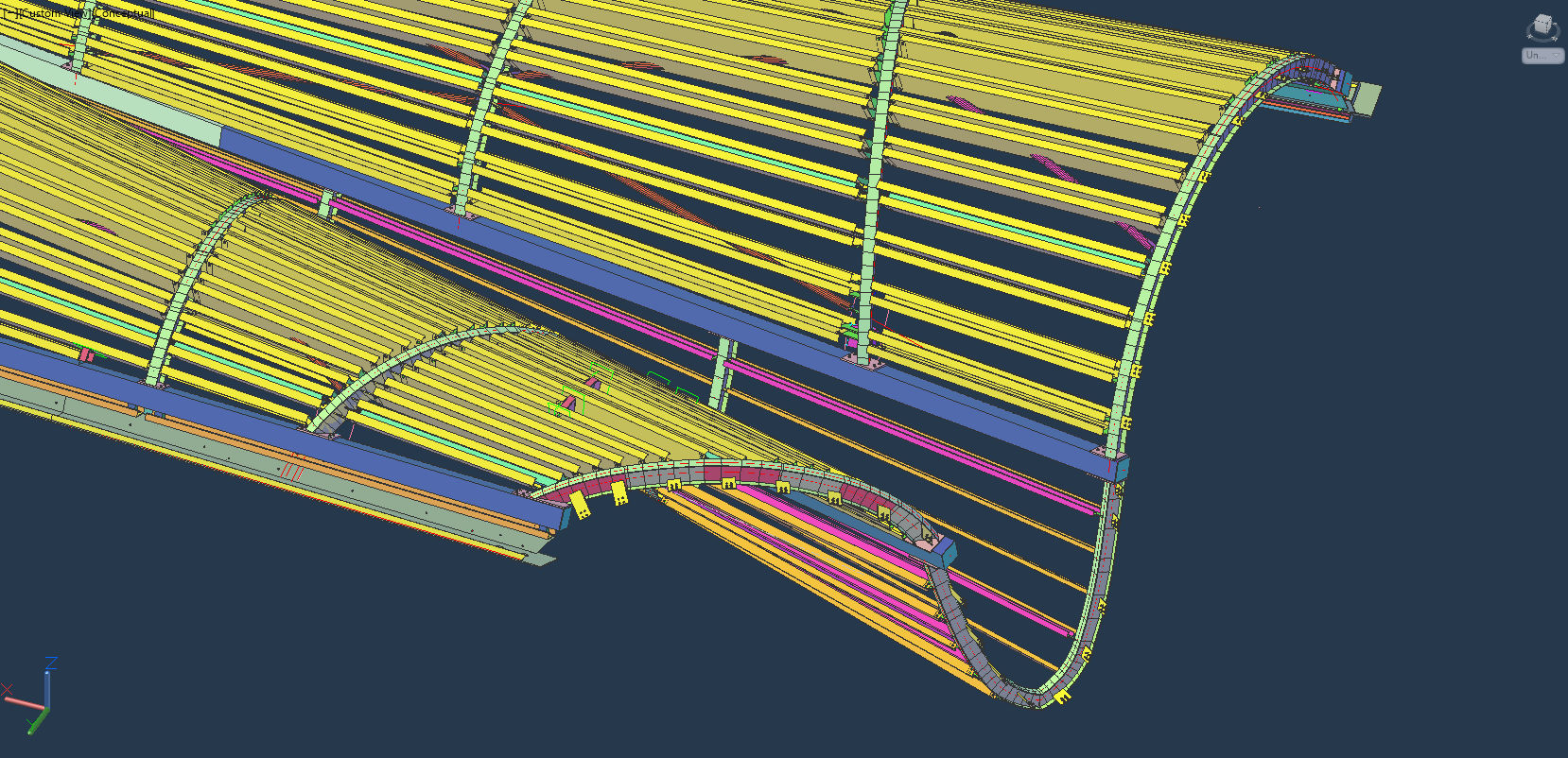

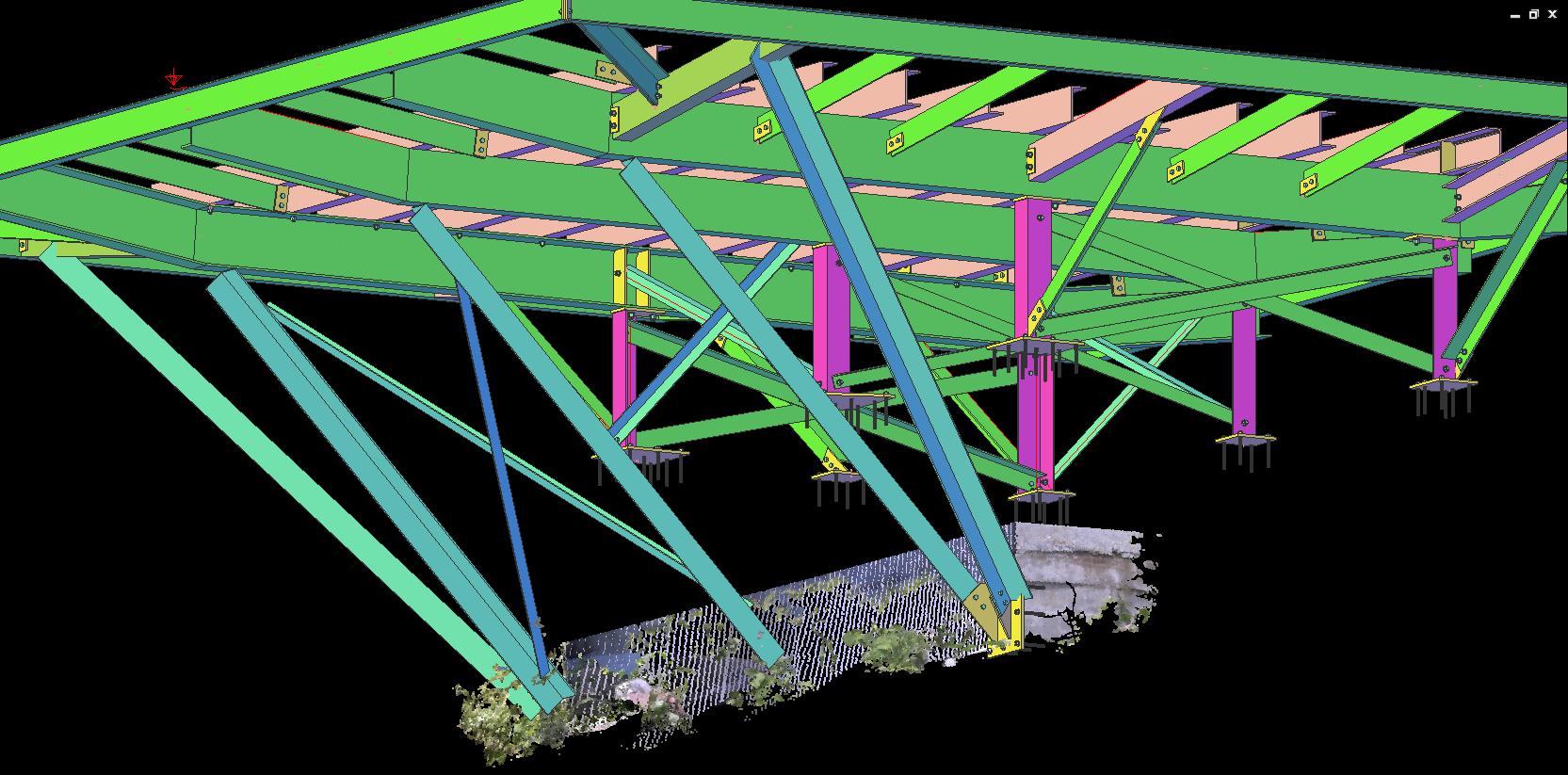

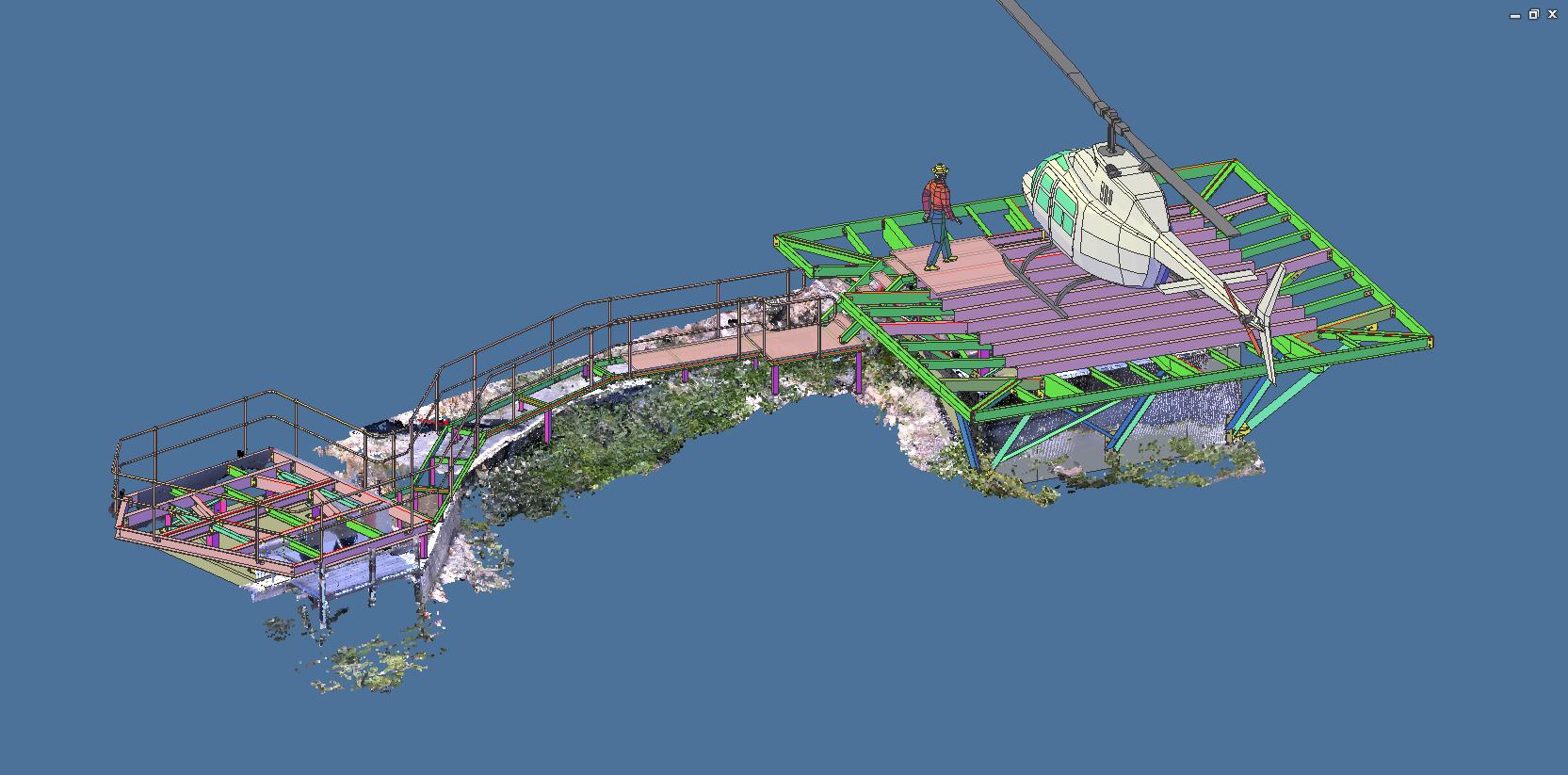

Client – Mineforce Australia. MDDM was awarded the contract to provide modelling and shop detailing services for approximately 550 tonnes of structural steelwork in the construction of a brand-new fertiliser production plant situated just 90 minutes west of Townsville, near Charters Towers. Using the vendor’s 3D models, surveys, and as-built laser scans, we meticulously created a comprehensive 3D master model of the entire plant. This enabled us to continuously verify construction set-out and erection against the model, allowing for adjustments during fabrication to align with as-built conditions. Additionally, two members of our team assumed project management and document control responsibilities throughout the entire 18-month construction period. This project stands as one of our most memorable accomplishments and is highly valued amongst the team. Client – Manufacturing Design Engineering Pty Ltd Midway Metals, a well-known steel supplier in Townsville, undertook a multi-million-dollar upgrade of their Ingham Road facility and offices in 2021. MDDM was contracted to provide the shop detailing of the new warehouse and office, including the structural steelwork. Mick Downey from MDE completed all the steel fabrication and erection, collaborating with McDonald Constructions, who managed all the civil and construction work. We extend our best wishes to Midway Metals for their fresh new headquarters. Client – Wilmar Sugar Australia. Inkerman Sugar Mill, located in Home Hill, North Queensland, required upgrades to both of its existing cane feeding stations due to aging infrastructure. MDDM worked alongside Wilmar Reliability Engineers and Project Engineers to develop a new state-of-the-art feeding station that will serve Inkerman Mill well into the future. Our scope encompassed the design, engineering, and detailing of new entry ramps, tippler structures, indexing/pusher arms, test weights, access stairs and platforms, concrete pits, and various other components. Being part of this project and working closely with the Wilmar team has been an exciting journey. Client – Mineforce Australia When Martin Hansen calls with a plan, you always know it’s going to be a good one! His plan involved designing and constructing two stainless-steel tanks, one with a capacity of five million litres and another with three million litres, along with their respective roofs. While MDDM has detailed many tanks, both large and small, and has experience with stainless and mild steel varieties, we had primarily worked with welded tanks in the past. However, when partnering with our trusted engineering company, ADM Engineering, we gladly accepted the challenge. We set about calculating all the critical bolting patterns, overlaps, and strake sizes required for this project. Additionally, we designed 40-meter and 32-meter diameter domed roofs to protect against the weather. Watching this project come together has been an absolute delight for all involved and has added a new skill to the growing list for the MDDM team. Client – Glencore Lead Smelter The brief from the MIM engineering team was clear: ‘An aging structure in need of replacing and upgrading.’ In response, our team of designers devised a bold plan to completely overhaul the existing structure. This involved lifting it by over two meters and integrating a new maintenance platform that was more than twice the size of the previous one. This elevation not only improved cleaning and maintenance underneath but also facilitated a steeper angle of discharge for gravity-fed pipelines, preventing potential blockages. Everything was installed safely and promptly during a plant shutdown. Client – Tully Sugar Mill The scope initially appeared straightforward: designing a duct from one side of a boiler to the other. However, the MDDM design team had to employ some innovative solutions for this project. They had to create custom 20-meter-long oval ducts to fit into a space where nothing should have fit, as well as develop a dual-angled, dual-knee brace support for the 1-meter diameter duct. Most of the ductwork had to be threaded through existing structures, often with only millimetres to spare. Fortunately, the TSL fabrication and installation team skilfully transformed our 3D models into reality, accomplishing this during both a crush and slack period. Client – Glencore Copper Smelter MDDM was engaged to replace the Copper Anode Bosh Tanks at Glencore’s Mount Isa Copper Smelter, as the two original tanks had reached the end of their operational lifespan. The highly corrosive environment had inflicted significant deterioration, prompting the decision to install new tanks constructed from duplex stainless-steel plate. We used a combination of cloud point data and site measurements to reverse engineer the tanks. The design incorporated better fabrication techniques, like folding corners where possible, strengthening the lifter robot supports, and changes to the sealing arrangements around the drive shafts. Due to the complexity of numerous moving components, many of which were slated for reuse, the project presented considerable challenges. Given the tanks’ pivotal role as around-the-clock production equipment, we had to ensure accuracy and function to provide uninterrupted, seamless operation for decades to come. Client – Evolution Mining In 2020, MDDM took on the task of reinventing access for EHM’s secondary cyclopack. The entire setup was scheduled for a one-meter elevation increase, aimed at facilitating improved cleaning access to the under and overflow launders. We meticulously engineered and designed a complete 360-degree walkway, complete with stairs to replace ladders, ensuring maintenance accessibility to each individual cyclone. The installation received widespread acclaim from EHM team members and abroad. Fast forward to 2022, we received another invitation, this time to replicate the same solution for the significantly larger primary cyclones. We replaced the existing eight individual platforms and ladders with another 360-degree platform and supporting steelwork. Furthermore, we accounted for the larger cyclone size and potential future expansion. We are confident that the EHM maintenance team will find their new access vastly superior to the old setup. Client – Wilmar BioEthanol In preparation for upcoming and future projects, Wilmar reached out to MDDM to conduct a comprehensive as-built laser scan at one of their processing plants near Sarina, Queensland. We utilised our Trimble X7 Laser Scanner to perform the scan, which spanned two days, ensuring thorough coverage of every area within the plant. The registered point cloud resulting from the scan has proven invaluable for modelling and clash checking in multiple replacement and upgrade projects. This has instilled confidence in the engineering team as they progress toward project implementation. Client – Wilmar Sugar Australia During the 2018/2019 maintenance season, Wilmar Sugar Australia replaced and upgraded two pan and condenser vessels at its Pioneer Sugar Mill, in the Burdekin, North Queensland. Client – JS Welding/Woollam Constructions Challenging simply does not begin to describe this project! Client – Civilplus Constructions & Woodfield Engineering A detailing job well out of the ordinary! Fitment of an all-new stainless steel helipad, walkway and lighthouse support framing on a remote island off Queensland’s coastline.

Scope – Shop Detail, Project Management.

Programs – Tekla Structures, Advance Steel, Navisworks.

Scope – Shop Detail

Programs – Tekla Structures.

Scope – Design, Certify and Detail.

Programs – Advance Steel, Navisworks, Trimble X7.

Scope – Design, Certification, Detail, Construction Support.

Programs – Advance Steel, AutoCAD, Trimble X7.

Scope – Design, Certification, Detail.

Programs – Advance Steel.

Scope – Design, Certification, Detail.

Programs – Advance Steel, AutoCAD, Faro X130.

Scope – Design, Certification, Detail.

Programs – Advance Steel, Trimble X7.

Scope – Design, Certification, Detail

Programs – Advance Steel, Trimble X7.

Scope – 3D Laser Scan

Scope – Shop details

Programs – Advance Steel & AutoCAD.

The project was a large undertaking by Wilmar and managed entirely in-house. One of the new pans has a 220-tonne capacity – the largest vessel ever fabricated by the company in-house. With the new vessel design being significantly larger, the existing roof had to be raised over 2m. Working closely with Wilmar and ADM Engineering, MDDM was involved from feasibility right through to shop detail stage. An adjacent skillion roof and suspended catwalk steelwork were also part of our scope. Working with a point cloud of the existing surrounds proved vital to the accuracy of our details and allowed for straightforward installation of all steelwork by the on-site crew.

Scope – Fabrication assistance

Programs – Advance Steel

MDDM was asked by Jason and his team to help find a simple, effective and efficient method to fabricate and construct this hugely complex structure. Utilising extensive laser etching and overlaying templates, the boilermakers were able to fabricate the curved plate work beams and numerous cleats either side, barely requiring the need to take the tape measure of their belt. With over two thousand unique pieces, we consider that some achievement.

We are immensely proud of the final outcome, which was achieved with no additional site work!

Scope – Steel detailing

Programs – Advance Steel and Recap Pro

Using a combination of cloud point data and AGM survey points, the new steel was modelled and detailed to connect to the existing concrete helipad and directly to the rocky island surface itself. Accuracy and construction methodology were absolutely crucial for this project, as the nearest hardware store was a 150km helicopter flight away!

All involved in this job very much look forward to handling more challenging and unique jobs like this in the future.

Agripower Fertiliser Production Plant

Warehouse & Office

Cane Bin Feeding & Tippling Station

Panel Tank Design & Construct

Sieve Screen Structure & Walkway

Boiler Over Fire Air Ducting

Copper Cathode Bosh Tanks

Cyclone Access Platforms

Processing Plant Laser Scan

Pioneer Mill Pan Stage Roof

JCU Central Plaza

Remote Island Helipad